ADA Advanced Design Alliance

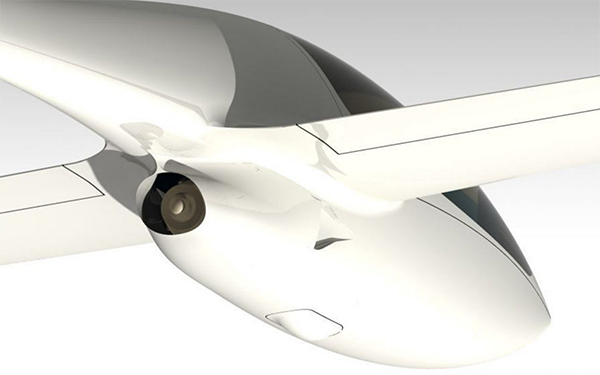

Aerobatic Jet Sailplane

The ADA Jet Glider project was initiated in August 2012 after a phone talk between Andrey Platygin (Advanced Design Alliance) and Eugene Zakharenkov (SnapRoll Aero) with a goal to build the fastest in the world unlimited aerobatics self-launching glider.

The glider features carbon fiber composite structures, symmetrical wing airfoil, jet engine H250 of Jetbeetle, 60l fuel capacity.

All materials published here, are with the courtesy of ADA. You can access an updated information on their website : adaexp.com

Preliminary data sheet

Specifications

| Occupant(s) | 1 |

| Length, m | 6,40 |

| Height, m | 1,80 |

| Span, m | 11 |

| Wing Area, sqm | 9,40 |

| Weights – MTOW, kg | 540 |

| Primary Structures Materials | Carbon Fiber Composites |

Performance

| Never Exceed Speed Vne, km/h (knots) | 460 (250) |

| L/D Ratio (expected) | 30 |

| Roll Rate, deg/s | 100 |

| Engine Max TO Thrust, kg (lbs) | 125 (275) |

| Engine Max Continuos Thrust, kg (lbs) | 113 (250) |

| Limit Load Factor | +10/-10 |

has been founded to satisfy the customers needs in affordable product design and engineering service based on contemporary state-of-the-art technologies.

ADA’s customers are those companies and individuals who have decided to go for outsourcing their engineering activity. Being a Ukrainian engineering service provider located in Kherson, they offer an acceptable level of engineering service cost.

Their experience has been obtained over long years of practical work with different companies and industries. Today their capabilities include product and parts conceptual and detailed design. The area of their expertise also covers structural design and structural analysis.

Having long years of experience in composite manufacturing and direct interface from electronic 3D master-model to the CNC milling machine they offer prototyping of customer product and consequent manufacturing.