Jonker Sailplanes Pty Ltd. (JS)

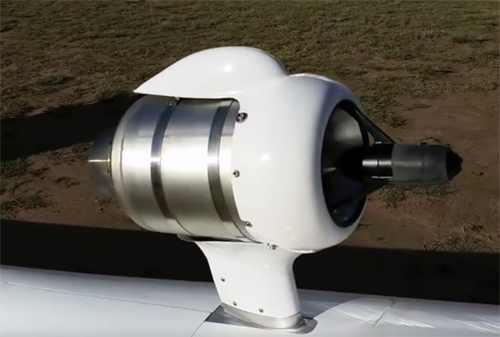

The Jonker JS1-TJ is the jet sustainer version of the JS1 Revelation, equipped with a 42kN thrust MD-TJ-42 jet engine. This engine has been specifically designed taking into account the requirements for a glider sustainer installation. The first flight of the JS1-TJ was on September 7th, 2011.

JS-1 Revelation is a glider designed and manufactured by Jonker in South Africa

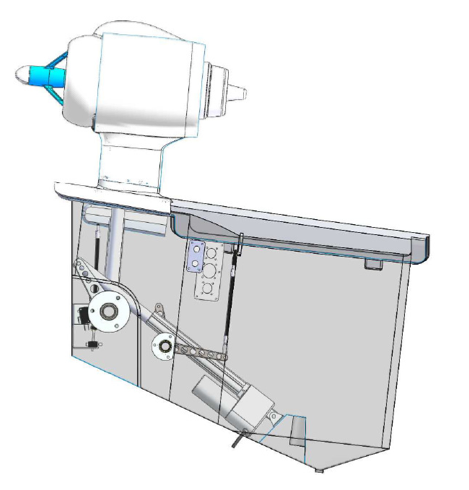

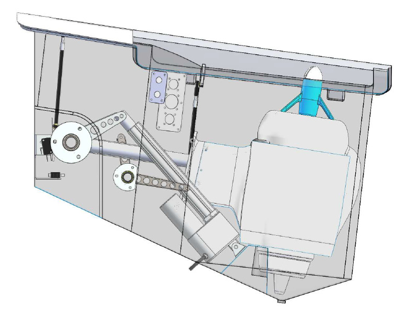

Overall Installation

The engine and other mechanical parts are mounted within a monocoque carbon-fibre sustainer box which is bolted to the fuselage around the engine bay cut-out.

Wiring harnesses have connectors at the sustainer box, and fuel lines have sealing, quick disconnect plugs. This modular design allows for easy access and good maintainability (allowing servicing and overhaul off the sailplane).

The engine bay is covered by three doors. There are two main doors on the port and starboard sides open during deployment and then close again once the engine has been fully deployed.

A third ‘finger door’ sits within a U-shaped cover-plate and folds away to make an opening into which the pylon fits flush with the surrounding fuselage.

In conjunction with a combined engine-pylon shroud, this arrangement minimises the drag of the deployed engine. It is estimated that the deployed engine has less drag than an extended undercarriage.

An electro-mechanical linear actuator is used to deploy the engine by rotating a tubular pylon structure.

Sliders operating in profiled cut-out arms connected to the pylon open and close the main doors in sequence as the engine deploys and stows again.

A sprung loaded arm operates the small ‘finger door’.

In the deployed position the engine is angled slightly to direct the hot jet efflux away from the fuselage and fin.

Also under consideration is supplementary post-curing of the fin leading edge to raise TG (glass temperature) as extra thermal protection.

The throttle is a sliding unit and is situated on the left hand seat panel lip.

There is a master switch with safety cover and engine/system information is displayed on a digital display unit.

Extention-retraction system

After evaluating various concepts considering safety, minimal space, rigidity, ease of maintenance, deployment time and manufacturability requirements, a single tubular pylon configuration was chosen.

The pylon is driven by an electric actuator controlled by the ECU. The sliding throttle system has detents for engine deployment and retraction. The electric actuator has built-in microswitches to limit the fully extended and retracted position, and in addition there are physical stops fitted to the engine box.